TTM

TTM, developed by Timetec Co., Ltd, is an advanced CAD system specifically designed for the shipbuilding industry. It offers comprehensive technical features that cover everything from 3D modeling to the creation of production drawings. With a focus on enhancing design and production efficiency, TTM combines cutting-edge technologies such as solid modeling, relationship-based modeling, parametric and template-driven designs, rule-based modeling, revision management, and undo/redo capabilities. Its intuitive and visually engaging interface ensures a seamless user experience, making it a powerful tool for modern shipbuilding projects.

Shipbuilding Initial Design

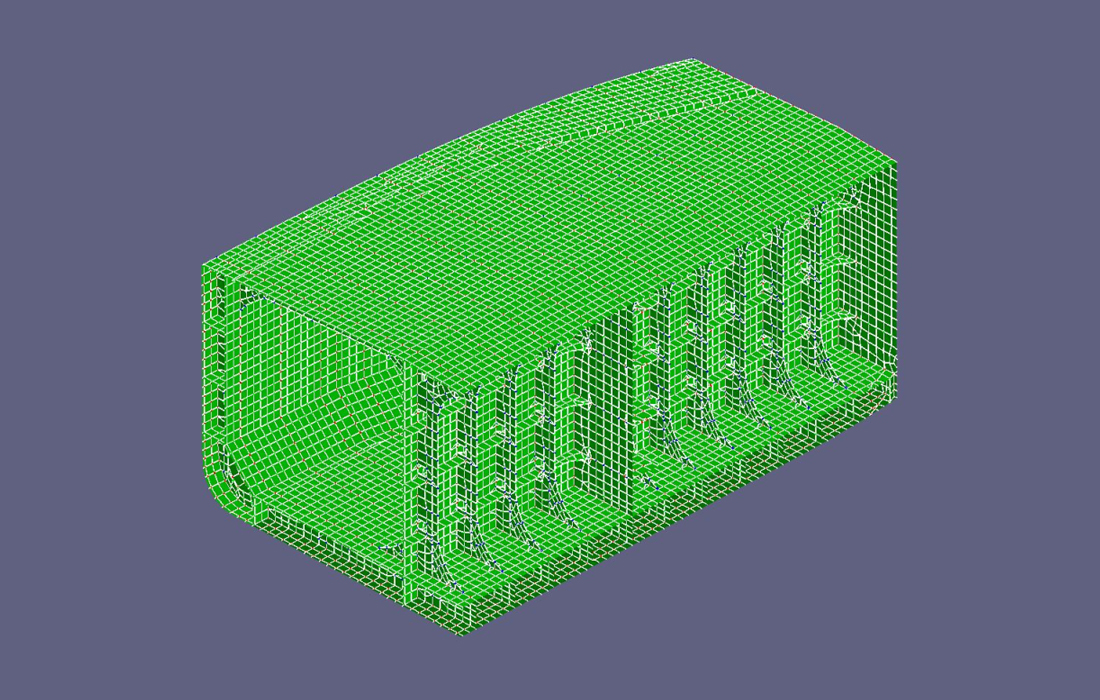

Initial Structure

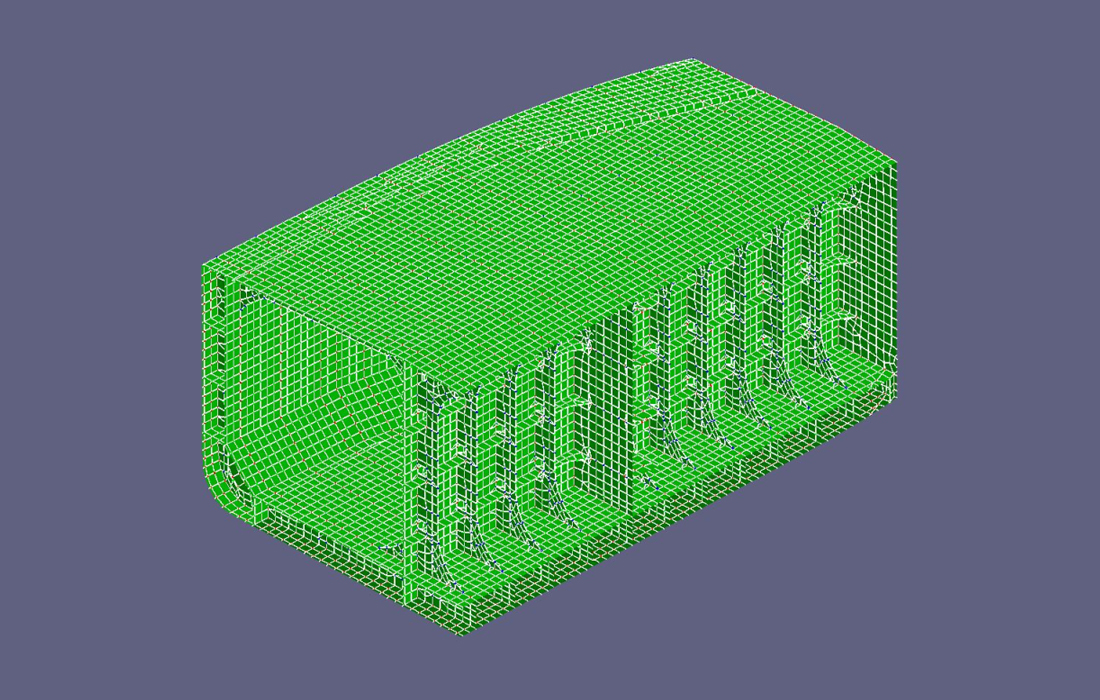

The Initial Structure stage establishes the core structural concept of the vessel at the earliest design phase, defining key geometry, primary load-bearing elements, and critical parameters that influence downstream processes.

By leveraging early 3D-based structural definition, this phase enhances project clarity and supports strategic decision-making before detailed design begins. A well-developed initial structure improves design consistency across disciplines, enables more accurate analysis and classification preparation, and sets a solid foundation for subsequent detailed structural development and production workflows.

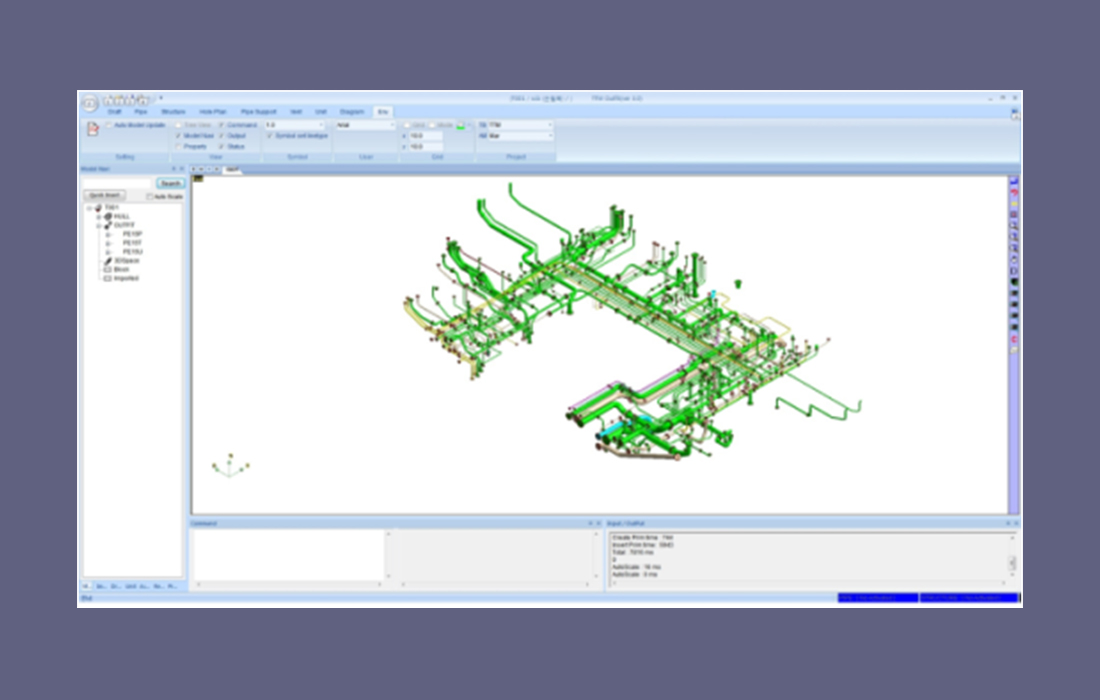

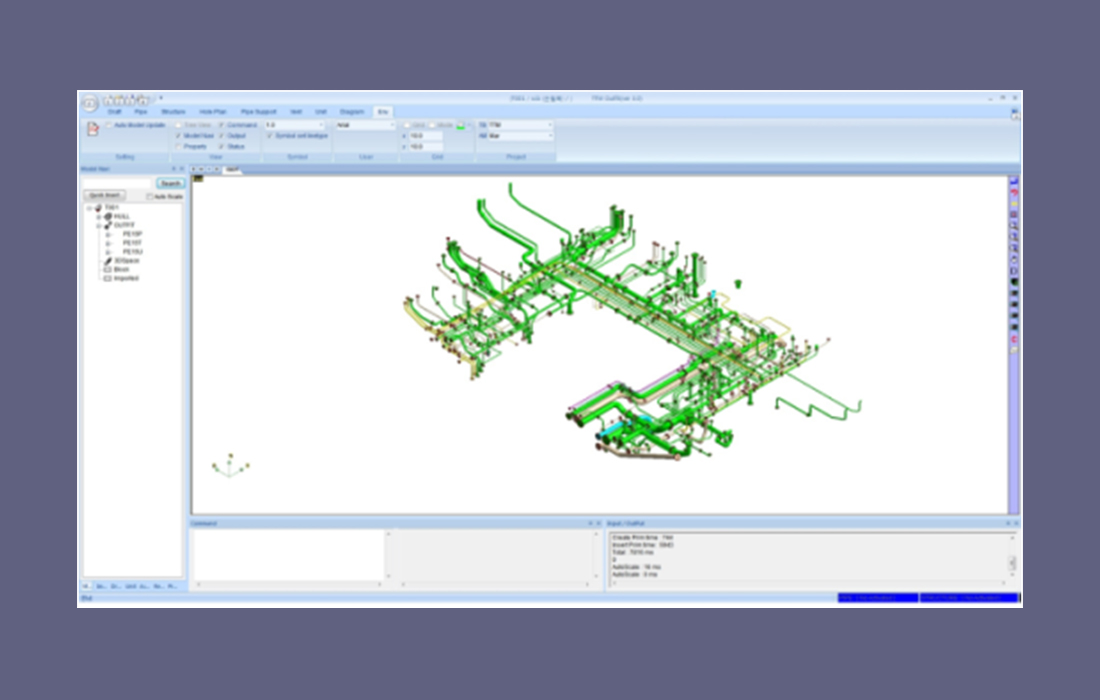

Initial Outfitting

The Initial Outfitting stage focuses on preliminary arrangement and layout of equipment and systems. At this stage, early arrangement planning, space allocation, and routing concepts help clarify integration challenges and opportunities across structural and mechanical systems.

Developing these early models supports reliable material quantity estimation, enhances coordination between disciplines, and helps identify potential design conflicts before detailed outfitting work begins. By establishing a consistent outfitting baseline early, the overall design process becomes more efficient and predictable.

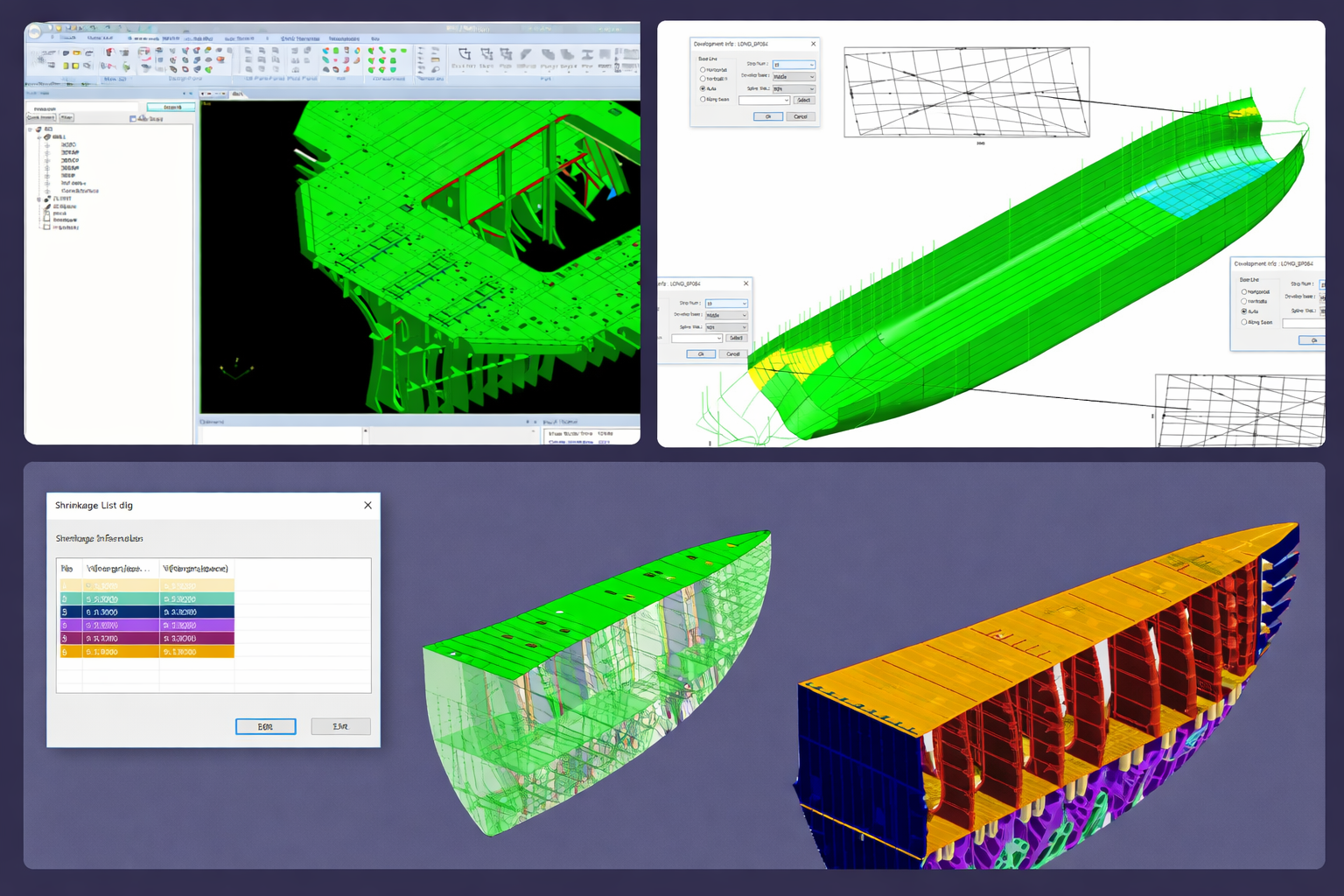

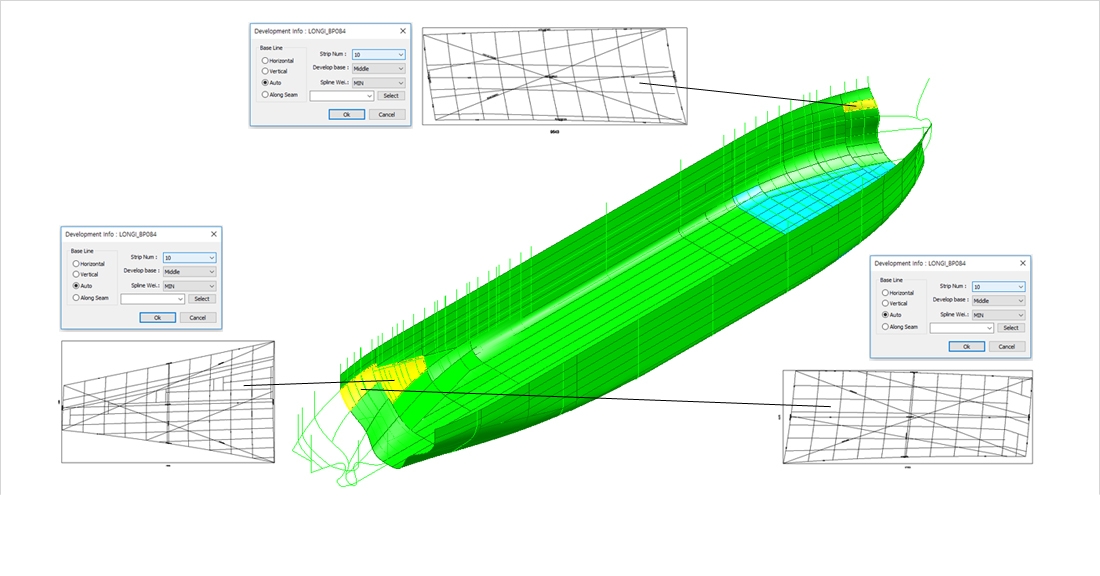

Shipbuilding Production Design

Hull Production

A high-efficiency module focused on manufacturing precision and real-time 2D/3D synchronization. It streamlines the transition from design to the shop floor, reducing production work time by up to 50%.

- Real-time 2D/3D Sync: Concurrent modeling and drafting for immediate updates.

- Integrated Production Tools: Built-in nesting, cutting, and assembly drawing batch work.

- Automated Rule Checks: Real-time error detection for bevels, holes, and member alignment.

- Shell Expansion: Advanced shell plate development and automated bending templates.

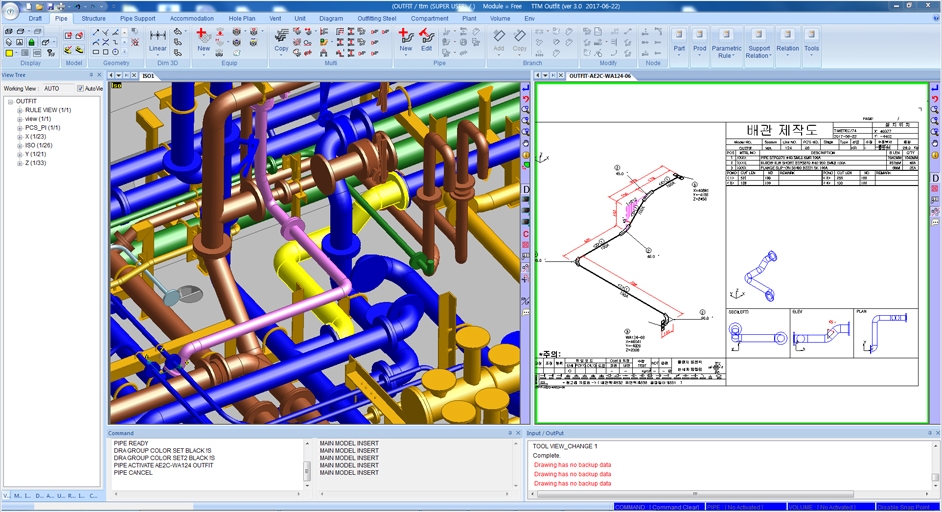

Outfitting Production

A comprehensive suite for detailed outfitting and installation. It automates the generation of production documents and ensures error-free layouts through advanced collision detection.

- Multi-Discipline Modeling: Covers Piping, Ducts, Cable Trays, and Accommodation.

- Automated Deliverables: Instant generation of Spool drawings, Cable schedules, and BOMs.

- Interference Control: Real-time collision checking to prevent on-site installation errors.

- Parametric Editing: Fast response times for equipment moves and system modifications.

Plant Design

Initial Structure

The Initial Structure stage establishes the core structural concept of the vessel at the earliest design phase, defining key geometry, primary load-bearing elements, and critical parameters that influence downstream processes.

By leveraging early 3D-based structural definition, this phase enhances project clarity and supports strategic decision-making before detailed design begins. A well-developed initial structure improves design consistency across disciplines, enables more accurate analysis and classification preparation, and sets a solid foundation for subsequent detailed structural development and production workflows.

Initial Outfitting

The Initial Outfitting stage focuses on preliminary arrangement and layout of equipment and systems. At this stage, early arrangement planning, space allocation, and routing concepts help clarify integration challenges and opportunities across structural and mechanical systems.

Developing these early models supports reliable material quantity estimation, enhances coordination between disciplines, and helps identify potential design conflicts before detailed outfitting work begins. By establishing a consistent outfitting baseline early, the overall design process becomes more efficient and predictable.

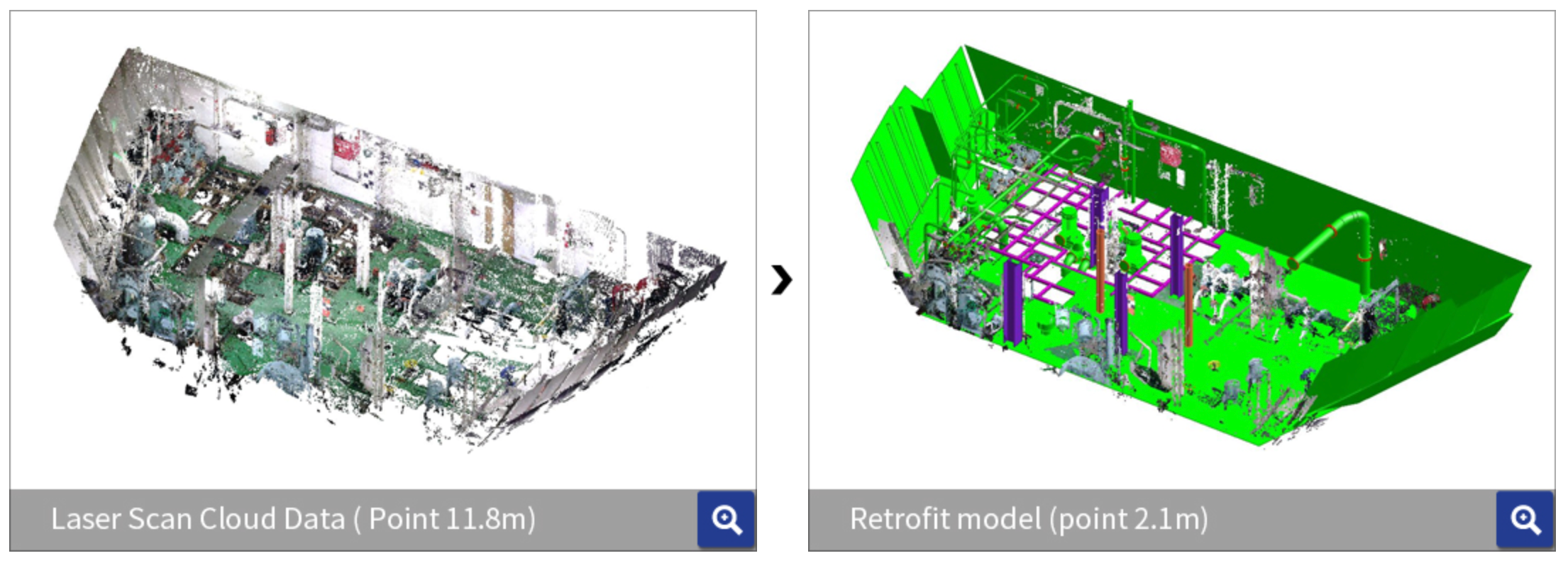

Ship Retrofit Design

Hull Production

S-Design is a specialized solution for ship modernization and retrofit projects, such as BWTS (Ballast Water Treatment System) installations and engine renewals. It utilizes 3D laser scan data (Point Clouds) as a high-precision foundation to transform existing vessel layouts into accurate, production-ready 3D models.

- Advanced Point Cloud Integration: Seamlessly handles large-scale scan data (10GB+) in formats like E57 and LAS, providing a precise 3D background for design.

- Intelligent Reverse Modeling: Tools to convert selected point cloud data directly into parametric pipes, plates, and profiles with smart alignment.

- Spec-Driven Design: Semi-automated routing and relation-based modeling that allow for fast equipment placement and modification.

- Automated Production Output: Instant generation of installation drawings, pipe spool drawings, and support details based on the reverse-engineered model.